03 April 2024

Charging into the Future: EU sets the standard with Battery Passport

Jeroen Bleker of ELEO, partner of the Battery Competence Center

My name is Jeroen Bleker and I am one of the three founders of ELEO. ELEO is manufacturing battery systems for electric vehicles and machines. We are not just focusing on electrification. We aim at improving the end application’s performance as compared to fuel-based performance. We do that by developing a modular battery platform, which can be used in many different applications. Allowing us to enable electrification in the broadest sense.

We founded the company in 2017. The idea was born during our student projects at the Eindhoven University of Technology (TU/e), during which we decided to aim our efforts at electrification, with an increasingly strong focus on developing and manufacturing battery systems. Our team now consists of some fifty people. In addition to former TU/e students, the team is made up of a wide variety of backgrounds and, by now, eleven nationalities.

ELEO’s identity is fresh, trendy and especially reliable. The name contains a referral to the Latin word for lion, which is also a symbol for the Netherlands. We are proud to be able to develop this technology in the Netherlands. Our recently completed building on the Automotive Campus in Helmond is a fantastic location to further develop our technology,

The ELEO team is fully geared for growth. That is why I focus, among other things, on the best possible way to further develop our team and furthermore, I am responsible for the collaboration with the Battery Competence Center.

As one of the founding fathers, ELEO has been involved in the BCC from the start. Of course, it is fantastic to collaborate with other parties in the field of batteries. We see that, despite ELEO’s short existence, we have gained a lot of expertise in the field of batteries, which, of course, is a fairly new technology. Other parties within the Battery Competence Center know more about, for example, manufacturing and upscaling of batteries, and for more fundamental research we can turn to TNO and the TU/e.

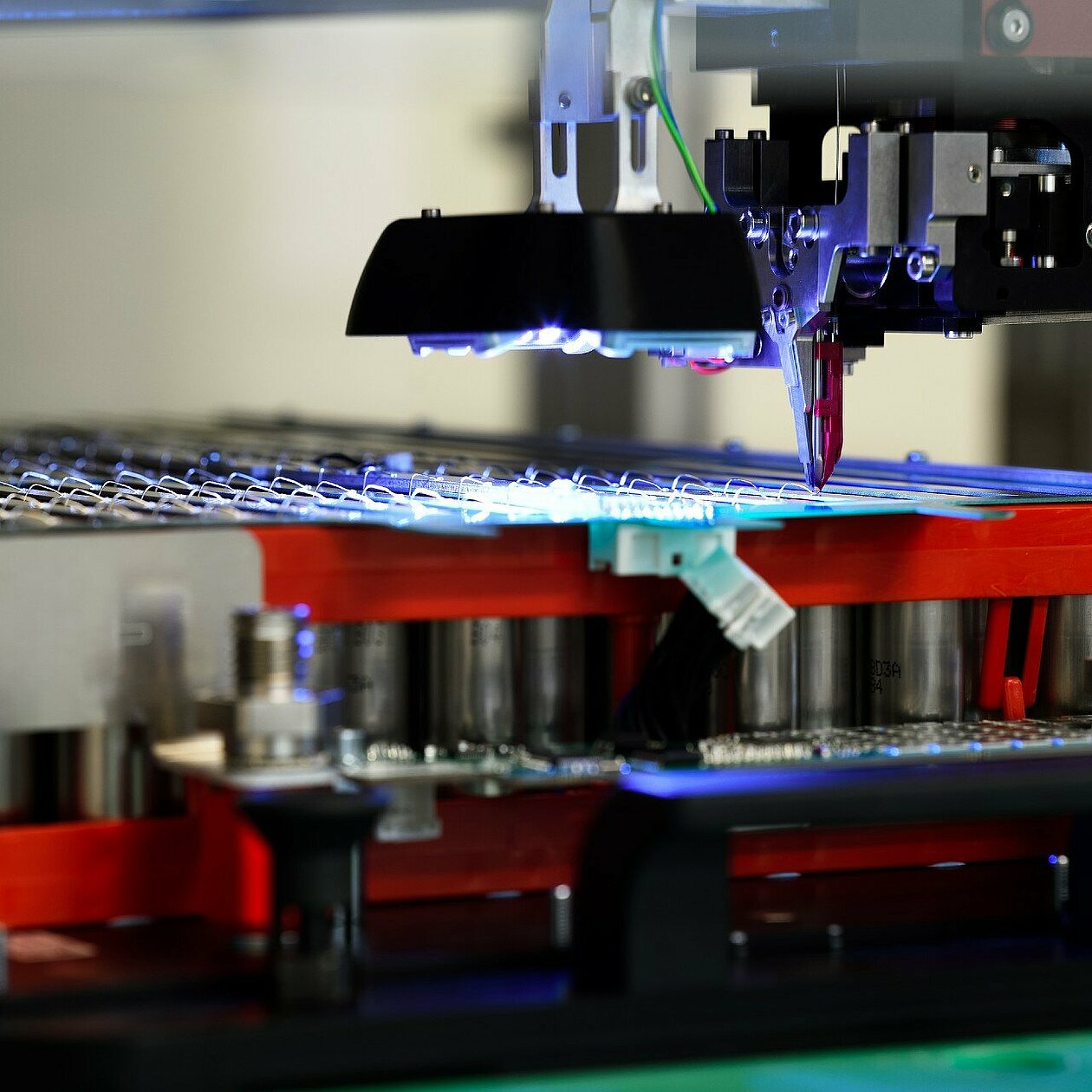

In our collaboration with the BCC, we try to gain the knowledge we are lacking and share our practical experiences with other partners. Within the BCC, we are further developing our battery systems, but we are also focusing on upscaling the manufacturing thereof. In our opinion, it is crucial to be able to manufacture battery systems in the Netherlands to play an important role in the value chain, in which other countries are focusing on manufacturing the necessary battery cells. We add the technology to optimally incorporate those cells into a system for the end application. We are fully automating the production of battery platform modules. And then, we quickly integrate those modules into the customer’s system. We have the specific technological expertise needed.

By working together, we use the knowledge and expertise of the partners involved. As a result, we gain more knowledge, but at the same time help other companies produce and grow.

To a certain extent, sustainability and electrification are the challenges we are facing as a society. We are mainly focusing on industrial applications, such as excavators and loaders, but we also offer solutions for inner city logistics, the maritime sector and storage. We also want to enable the industry, with all its machinery and vehicles, to become more sustainable and electrified. We do that by supplying systems that allow the industry to bring electric applications to market that perform better than fuel-based applications.

We are continuously further developing our battery platform to make it even easier to integrate into the end application. Furthermore, the specs are getting better and better of course and we are focusing on maximizing life span. Because we are learning more and more about battery cells, we know exactly how to use them optimally. Potentially, batteries can be used again after they have first been used, allowing to use the full potential of the cells before the materials are recycled.

In addition to lower CO2 emissions thanks to electrification, people in the Netherlands will appreciate the construction worker using electric machinery on the pavement. When construction is underway in the city center, you can hear and smell the diesel engine and, in the future, this will no longer be the case. Ultimately, what we do, helps the larger mission to make the world more sustainable.

We are developing and manufacturing our battery systems within the region and we are therefore interested in parties that can help us develop those systems. It is good to show the region, and the Netherlands as a whole, that we are experts in battery technology, from cell to system, to create international impact. It is great that we, as part of the BCC, are working together with parties that want to help the development, supply chain or production of battery systems.

The Netherlands has a lot of innovative power. Not only with respect to the well-known companies, but rather also with respect to startups.